Relojes De Mujer De Oro A La Moda Reloj De Diamantes De Imitación De Lujo Clásico De Ginebra | Shopee Colombia

Relojes de oro: todo lo que tienes que saber sobre estas joyas de Rolex, Chopard, Omega y Hublot | GQ España

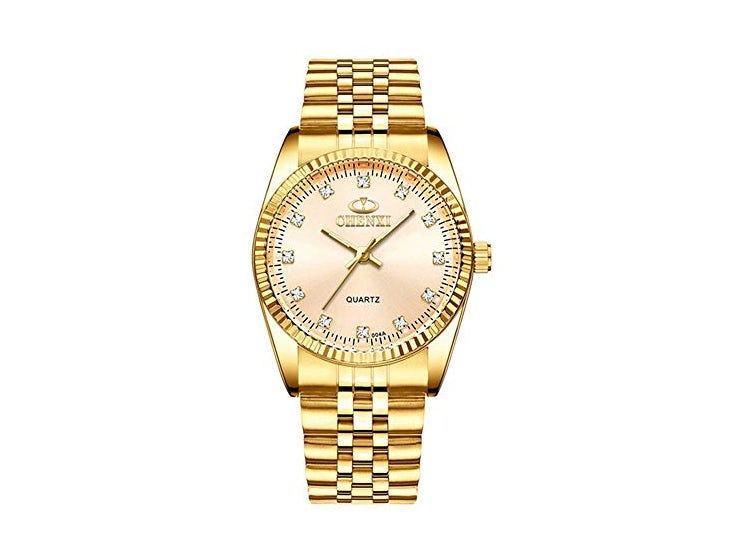

Ripley - PAREJA RELOJES SUIZOS MARCA ORO RELOJ HOMBRES MUJERES ACERO INOXIDABLE IMPERMEABLE RELOJ DE CUARZO

![Reloj oro 18k Royce mujer redondo panter brillo liso mate [AB4264] Reloj oro 18k Royce mujer redondo panter brillo liso mate [AB4264]](https://www.inmaculadaromero.com/34451-thickbox_default/reloj-oro-18k-royce-mujer-redondo-panter-brillo-liso-mate-ab4264-.jpg)